Igwe Ngwuputa Ihe CNC PHD2020C maka efere ígwè

| Nhazi kachasịihenha | Dayameta | φ2000mm |

| Efere | 2000 x 2000mm | |

| Oke ọkpụrụkpụ efere edoziri | 100 mm | |

| oche ọrụ | Obosara oghere T | 22 mm |

| Isi ike igwu ala | Oke dayameta mkpọpu ala nke igwe ntụgharị ígwè dị elu | φ50 mm |

| Dayameta kachasị elu nke ihe eji egwu simenti nke carbide | φ40 mm | |

| Oke dayameta igwe ọka cutter | φ20mm | |

| Mkpụcha spindle | BT50 | |

| Ike moto bụ isi | 22kW | |

| Oke ike spindle torque ≤750r/min | 280Nm | |

| Anya site na nsọtụ ala nke ihu nkespindlena tebụl ọrụ | 250—600 mm | |

| Njem ogologo oge nke Gantry (axis-x) | Oke kachasịStrok | 2050 mm |

| Ọsọ ngagharị nke X-axis | 0—8m/min | |

| Ike moto servo X-axis | Ihe dịka 2 × 1.5kW | |

| Mmegharị nke isi ike n'akụkụ(Axis Y) | Oke mkpọtụ nke isi ike kachasị | 2050mm |

| Ike moto servo nke Y-axis | Ihe dị ka 1.5kW | |

| Njem nri nke isi ike(Axis Z) | Njem Z-axis | 350 mm |

| Ike moto servo nke Z-axis | Ihe dị ka 1.5 kW | |

| izi ezi nke ọnọdụ | X-axis,Axis Y | 0.05mm |

| Izi ezi ọnọdụ ugboro ugboro | X-axis,Axis Y | 0.025mm |

| Sistemụ ikuku na-efe efe | Nrụgide ikuku achọrọ | ≥0.8MPa |

| Ike moto mbufe mgbawa | 0. 45kW | |

| Jụụ | Ụdị oyi dị n'ime | oyi ikuku |

| Ụdị oyi dị na mpụga | Mmiri oyi na-agbagharị | |

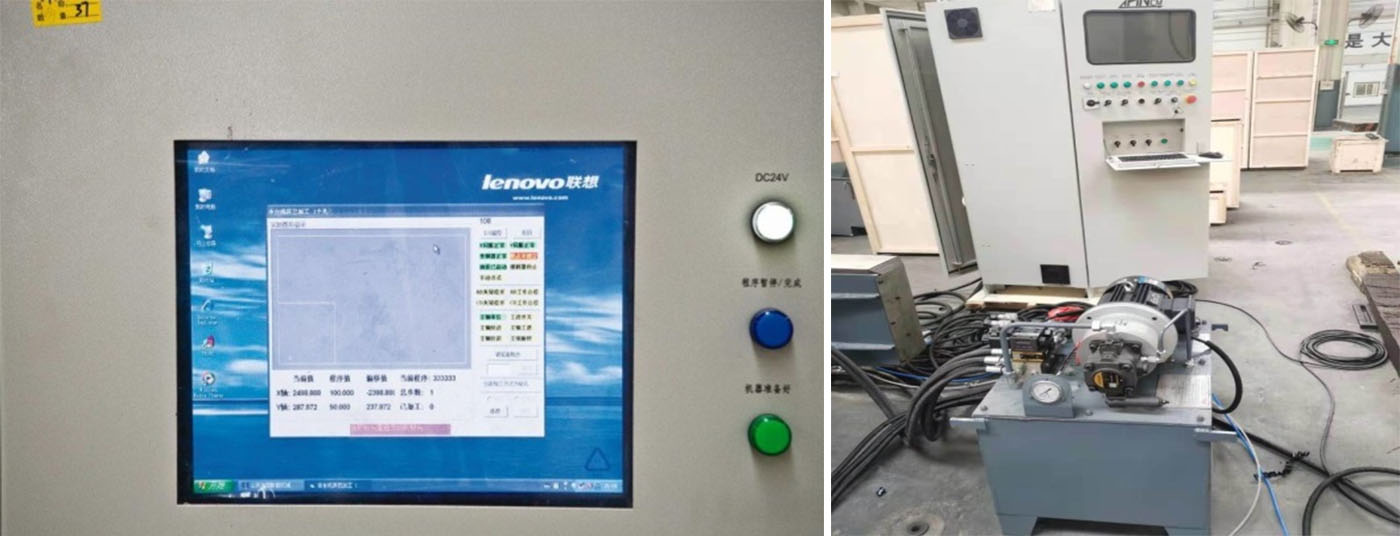

| Sistemụ eletriki | CNC | Siemens 808D |

| Ọnụọgụ nke CNC axes | 4 | |

| Isi igwe | Ibu | Ihe dị ka kilogram 8500 |

| Akụkụ mkpokọta(L× W × H) | Ihe dị ka 5300(3300)×3130 × 2830 mm |

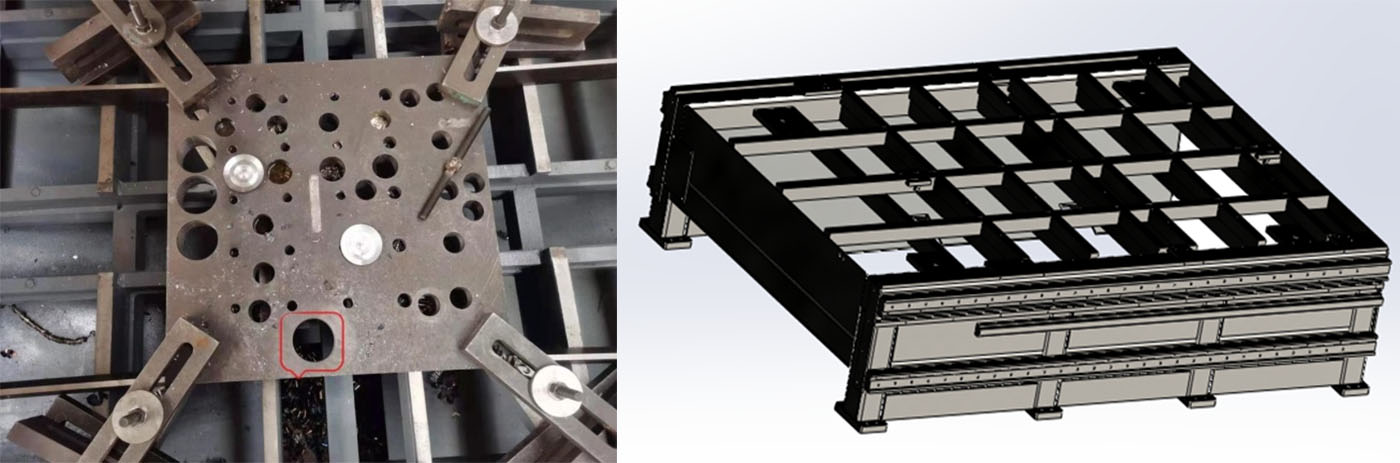

1. Igwe a nwere ihe ndina na ihe eji emegharị emegharị ogologo oge, tebụl gantry na nke transverse, isi ike ịgba mmiri, ngwaọrụ mwepụ mgbawa, sistemụ pneumatic, sistemụ oyi ịgba mmiri, sistemụ mmanụ etiti, sistemụ eletriki na wdg.

2. Isi ike nke olulu mmiri na-eji spindle ziri ezi nke emere na Taiwan, nke nwere ezigbo nhazigharị na ezigbo nkwụsi ike. E ji oghere taper BT50 mee ya, ọ dị mfe ịgbanwe ngwaọrụ. Ọ nwere ike ijide ma ihe ndọbagharị na ihe ndọba carbide simenti, yana ọtụtụ ojiji. Enwere ike iji obere ihe ndọba njedebe maka igwe egwe ọkụ dị mfe. Moto ugboro ugboro agbanwe agbanwe na-anya spindle ahụ, nke nwere ọtụtụ ojiji.

3. Ngwaọrụ igwe ahụ nwere axes CNC anọ: axes nhazi gantry (axis x, double drive); axes nhazi transverse (axis Y) nke isi ike igwu ala; axes nri isi ike igwu ala (axis Z). Axes CNC ọ bụla na-eduzi site na usoro ntuziaka mpịakọta ziri ezi ma na-eji AC servo moto + skru bọọlụ na-anya ya.

4. Ngwaọrụ igwe ahụ nwere ihe e ji ebuga mgbawa ígwè dị larịị n'etiti akwa igwe ahụ. A na-achịkọta iberibe ígwè ndị ahụ n'ime ihe e ji ebuga mgbawa, a na-ebugakwa iberibe ígwè ndị ahụ na ihe e ji ebuga mgbawa, nke dị nnọọ mma maka iwepụ mgbawa; A na-emegharị ihe e ji ekpofu mmiri ahụ.

5. A na-etinye mkpuchi nchebe na-agbanwe agbanwe na okporo ụzọ nduzi x-axis na y-axis n'akụkụ abụọ nke ngwaọrụ igwe.

6. Sistemụ oyi ahụ nwere mmetụta nke oyi dị n'ime na oyi dị n'èzí.

7. Sistemụ CNC nke ngwaọrụ igwe ahụ nwere Siemens 808D na wiil aka eletrọniki, nke nwere ọrụ dị ike na ọrụ dị mfe. E tinyere ya na interface RS232 ma nwee ọrụ nhazi nlele na nlele ọzọ. Interface arụmọrụ nwere ọrụ nke mkparịta ụka igwe mmadụ, nkwụghachi njehie na mkpu akpaka, ma nwee ike ime mmemme akpaka nke CAD-CAM.

| Mba. | Aha | Akara aha | Obodo |

| 1 | Lokporo ụzọ nduzi inear | HIWIN/PMI/ABBA | Taiwan, Chaịna |

| 2 | Abụọ skru bọọlụ | HIWIN/PMI | Taiwan, Chaịna |

| 3 | CNC | Siemens | Jamanị |

| 4 | moto servo | Siemens | Jamanị |

| 5 | Onye ọkwọ ụgbọala Servo | Siemens | Jamanị |

| 6 | Ntugharị nkenke | KENTUR | Taiwan, Chaịna |

| 7 | Mmanụ e ji eme mmanụ nke etiti | BIJUR/HERG | USA / Japan |

Rịba ama: Nke dị n'elu bụ onye na-ebubata ngwaahịa anyị. A ga-eji otu ihe dị mma nke ụdị ngwaahịa ndị ọzọ dochie ya ma ọ bụrụ na onye na-ebubata ngwaahịa dị n'elu enweghị ike ịnye ihe ndị dị na ya ma ọ bụrụ na ihe pụrụ iche ọ bụla dị.

Nkọwapụta Nkọwa Ụlọ Ọrụ  Ozi Ụlọ Ọrụ

Ozi Ụlọ Ọrụ  Ike Mmepụta Kwa Afọ

Ike Mmepụta Kwa Afọ  Ikike azụmaahịa

Ikike azụmaahịa