Igwe igwe PLM4020 nke a na-ebugharị ebugharị CNC Plate Drilling Machine

(1) Ahụ nke igwe na ogwe obe ahụ dị n'ụdị e ji agwakọta ihe, mgbe e mechara ọgwụgwọ okpomọkụ zuru oke, nke ziri ezi nke ukwuu. E ji ígwè a kpụrụ tebụl ọrụ, tebụl na-amị amị transversal na ram.

(2) Sistemụ draịva servo nke akụkụ abụọ na X axis na-eme ka mmegharị gantry ziri ezi, yana ezigbo nha nhata nke Y axis na X axis.

(3) Tebụl ọrụ ahụ na-eji ụdị kwụsiri ike, ígwè a kpụrụ akpụ dị elu na usoro ịkpụ ihe dị elu, yana nnukwu ikike ibu.

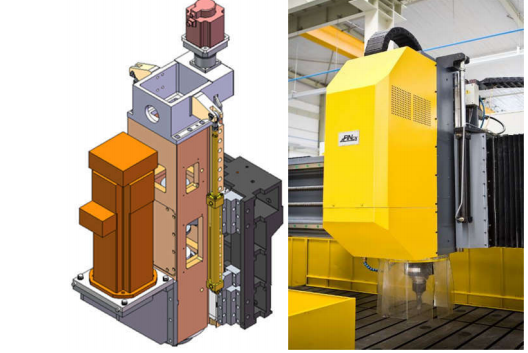

(4) Oche nwere ike isi ike, nke nwere ike isi ike na-anabata usoro ntinye azụ-na-azụ, nke nwere ike isi ike pụrụ iche nke nwere skru dị elu.

(5) Njem kwụ ọtọ (Z-axis) nke isi ike na-eduzi site na ụzọ ndị na-eduzi roller linear nke edoziri n'akụkụ abụọ nke ram ahụ, nke nwere ezigbo nkenke, oke mmịgharị na obere ihe mgbochi esemokwu.

(6) Igbe ike ịgba ihe bụ ụdị spindle siri ike, nke na-anabata spindle oyi dị n'ime Taiwan BT50. Oghere spindle cone nwere ngwaọrụ nhicha, ma nwee ike iji simenti carbide eme ihe dị n'ime oyi, yana ezigbo nkenke. A na-eji moto servo spindle ike dị elu na-anya spindle ahụ site na eriri synchronous, oke mbelata bụ 2.0, ọsọ spindle bụ 30~3000r/min, oke ọsọ ahụ dịkwa obosara.

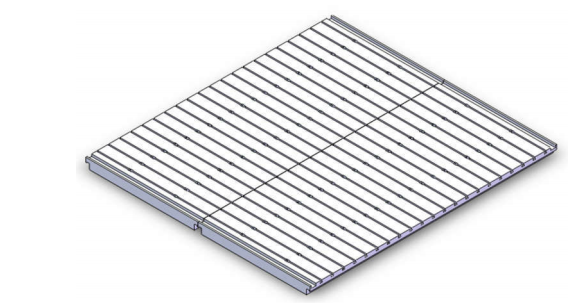

(7) Igwe a na-eji ihe mkpofu chip abụọ dị larịị n'akụkụ abụọ nke tebụl ọrụ. A na-anakọta iberibe ígwè na ihe mkpofu na ihe mkpofu na ihe mkpofu chip. A na-ebuga iberibe ígwè ndị ahụ na ihe mkpuchi chip, nke dị nnọọ mma maka iwepụ chip. A na-emegharị ihe mkpuchi ahụ.

(8) Igwe a na-enye ụdị ụzọ abụọ isi mee ka oyi dị n'ime na nke mpụga. A na-eji ọkpọ mmiri dị elu eme ihe iji nye ihe mkpuchi dị mkpa maka ime ka oyi dị n'ime, yana nrụgide dị elu na nnukwu mmiri.

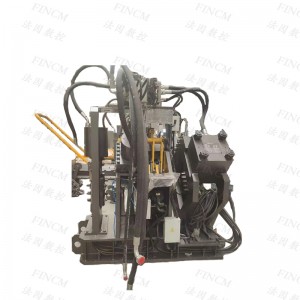

(9) Igwe a nwere sistemụ mmanụ akpaka, nke na-awụnye mmanụ mmanụ n'ime blọk linear guide pair sliding, bọọlụ skru pair skru na mkpụgharị nke akụkụ ọ bụla mgbe niile iji mee mmanụ kachasị mma na nke a pụrụ ịtụkwasị obi.

(10) E nwere mkpuchi nchekwa ígwè anaghị agba nchara nke e ji ígwè na-anaghị agba nchara rụọ, e nwekwara mkpuchi nchekwa na-agbanwe agbanwe nke e ji ígwè na-eduzi Y rụọ.

(11) Ngwaọrụ igwe ahụ nwekwara ihe nchọta ihu fotoelectric iji mee ka ebe ọrụ gburugburu dị mfe.

(12) E ji ihe nchekwa zuru oke hazie ma tinye ngwaọrụ igwe a. E nwere ikpo okwu ije, ihe nchekwa, na steepụ ịrịgo n'akụkụ ogidi ahụ iji hụ na nchekwa nke ndị ọrụ na-arụ ọrụ na ndị na-arụzi ya dị mma. A na-etinye mkpuchi PVC dị nro na-acha ọcha gburugburu ogwe isi.

(13) Sistemụ CNC nwere Siemens 808D ma ọ bụ Fagor 8055, nke nwere ọrụ dị ike. Njikọ ọrụ nwere ọrụ nke mkparịta ụka na igwe mmadụ, nkwụghachi njehie na mkpu akpaka. Sistemụ ahụ nwere wiil aka eletrọniki, nke dị mfe ịrụ ọrụ. Site na iji kọmputa a na-ebugharị ebugharị, enwere ike ime mmemme akpaka CAD-CAM mgbe etinyere ngwanrọ kọmputa dị elu.

| ihe | Aha | Uru |

|---|---|---|

| Nha efere kachasị elu | L x W | 4000 × 2000 mm |

| Nha efere kachasị elu | Dayameta | Φ2000mm |

| Nha efere kachasị elu | Oke ọkpụrụkpụ | 200 mm |

| Tebụl Ọrụ | Obosara oghere T | 28 mm (ọkọlọtọ) |

| Tebụl Ọrụ | Akụkụ tebụl ọrụ | 4500x2000mm (LxW) |

| Tebụl Ọrụ | Ibu Ibu Na-ebu Ibu | Tọn atọ/㎡ |

| Spindle Ịkpọsa Mmiri | Oke dayameta nke mkpọpu ala | Φ60 mm |

| Spindle Ịkpọsa Mmiri | Dayameta Tapping Kachasị Elu | M30 |

| Spindle Ịkpọsa Mmiri | Ogologo Mkpanaka nke spindle na dayameta oghere | ≤10 |

| Spindle Ịkpọsa Mmiri | RPM | 30~3000 r/min |

| Spindle Ịkpọsa Mmiri | Ụdị teepu spindle | BT50 |

| Spindle Ịkpọsa Mmiri | Ike moto spindle | 22kW |

| Spindle Ịkpọsa Mmiri | Oke Torque (n≤750r/min) | 280Nm |

| Spindle Ịkpọsa Mmiri | Anya site na elu ala Spindle ruo na tebụl ọrụ | 280~780 mm (enwere ike ịgbanwe dịka ọkpụrụkpụ ihe si dị) |

| Njem Ogologo Oge Gantry (Axis X) | Njem Kasị Elu | 4000 mm |

| Njem Ogologo Oge Gantry (Axis X) | Ọsọ mmegharị n'akụkụ X axis | 0~10m/min |

| Njem Ogologo Oge Gantry (Axis X) | Ike moto servo nke X axis | 2 × 2.5kW |

| Mmegharị Mgbanwe Spindle (Axis Y) | Njem Kasị Elu | 2000mm |

| Mmegharị Mgbanwe Spindle (Axis Y) | Ọsọ mmegharị n'akụkụ axis Y | 0~10m/min |

| Mmegharị Mgbanwe Spindle (Axis Y) | Ike moto servo nke axis Y | 1.5kW |

| Mmegharị Nri Spindle (Axis Z) | Njem Kasị Elu | 500 mm |

| Mmegharị Nri Spindle (Axis Z) | Ọsọ nri nke axis Z | 0~5m/min |

| Mmegharị Nri Spindle (Axis Z) | Ike moto servo nke axis Z | 2kW |

| Izi ezi nke ọnọdụ | Axis X, axis Y | 0.08/0.05mm/njem zuru oke |

| Izi ezi ọnọdụ a na-emegharị emegharị | Axis X, axis Y | 0.04/0.025mm/njem zuru oke |

| Sistemụ haịdrọlik | Nrụgide/Ọnụego mmiri nke mgbapụta hydraulic | 15MPa /25L/nkeji |

| Sistemụ haịdrọlik | Ike moto mgbapụta haịdrọlik | 3.0kW |

| Sistemụ ikuku na-efe efe | Nrụgide ikuku agbakọrọ agbakọ | 0.5 MPa |

| Sistemụ mwepụ na oyi nke ihe mkpofu | Ụdị mwepụ ihe mkpofu | Ayika efere |

| Sistemụ mwepụ na oyi nke ihe mkpofu | Mwepụ ihe mkpofu Nọmba | 2 |

| Sistemụ mwepụ na oyi nke ihe mkpofu | Ọsọ mwepụ ihe mkpofu | 1m/nkeji |

| Sistemụ mwepụ na oyi nke ihe mkpofu | Ike Moto | 2 × 0.75kW |

| Sistemụ mwepụ na oyi nke ihe mkpofu | Ụzọ oyi | Oyi dị n'ime + Oyi dị n'èzí |

| Sistemụ mwepụ na oyi nke ihe mkpofu | Nrụgide Kachasị | 2MPa |

| Sistemụ mwepụ na oyi nke ihe mkpofu | Oke ọsọ | 50L/nkeji |

| Sistemụ eletrọniki | Sistemụ njikwa CNC | Siemens 808D |

| Sistemụ eletrọniki | Nọmba CNC Axis. | 4 |

| Sistemụ eletrọniki | Ike zuru oke | Ihe dịka 35kW |

| Akụkụ N'ozuzu | L×W×H | Ihe dị ka 10×7×3m |

| Mba. | Aha | Akara aha | Obodo |

|---|---|---|---|

| 1 | Ụgbọ okporo ígwè nduzi nke nwere akara roller | Hiwin | Chaịna Taiwan |

| 2 | Sistemụ njikwa CNC | Siemens/Fagor | Jamanị/Spain |

| 3 | Na-enye servo moto na servo ọkwọ ụgbọala | Siemens/Panasonic | Jamanị/Japan |

| 4 | Mkpụgharị kpọmkwem | Spintech/Kenturn | Chaịna Taiwan |

| 5 | Valvụ hydraulic | Yuken/Justmark | Japan/China Taiwan |

| 6 | Ọgba mmanụ | Justmark | Chaịna Taiwan |

| 7 | Sistemụ mmanụ akpaaka | Herg/BIJUR | Ndị Japan/Ndị Amerịka |

| 8 | Bọtịnụ, ihe ngosi, ihe eletrọniki dị ala nke nwere obere voltaji | ABB/Schneider | Jamanị/France |

| Mba. | Aha | Nha | Ọnụọgụ. |

|---|---|---|---|

| 1 | ihe nchọta ihu anya | 1 ibe | |

| 2 | Snaị heksagọn dị n'ime | 1 setịpụ | |

| 3 | Ihe njide ngwaọrụ na ihe ndọda stud | Φ40-BT50 | 1 ibe |

| 4 | Ihe njide ngwaọrụ na ihe ndọda stud | Φ20-BT50 | 1 ibe |

| 5 | Agba ndị ọzọ | – | Keg abụọ |

1. Ọkụ eletrik: ahịrị atọ nke ise 380+10%V 50+1HZ

2. Nrụgide ikuku agbakọrọ agbakọ: 0.5MPa

3.Okpomọkụ: 0-40℃

4.Iru mmiri: ≤75%